How Important is Janka Rating – Avoid These Pitfalls When Using Janka Hardness Scale to Choose Flooring

Janka rating is a measurement of a wood’s resistance to dents and scratches, and is used to determine its suitability for various projects – including floors. But don’t be mislead. Janka rating doesn’t tell the whole story. Learn how to choose the most scratch resistant and durable hardwood flooring.

As a buyer of hardwood flooring I would just take the sellers word for it – whatever flooring they said had the hardest finish I would believe. But, when I started selling wood floors I wanted a standardized rating system for durability so we could point to that and give the customer direction. But, with more research and testing it became apparent that where a type of wood lands on the Janka Hardness Scale only tells half the story.

What is Janka Rating – Janka Hardness Scale

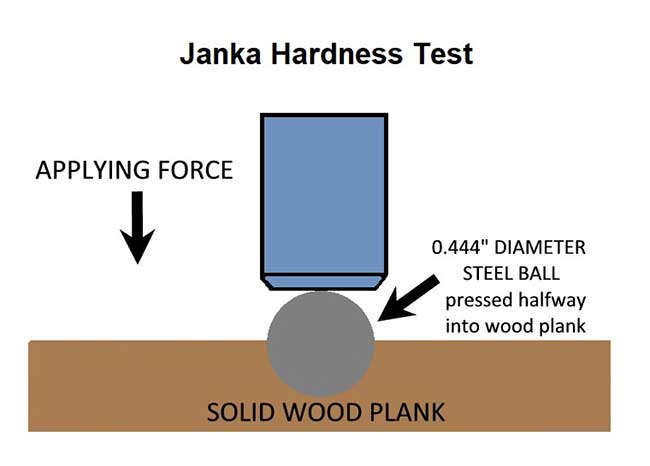

Gabriel Janka, an Austrian wood researcher, invented the Janka hardness test in 1906.

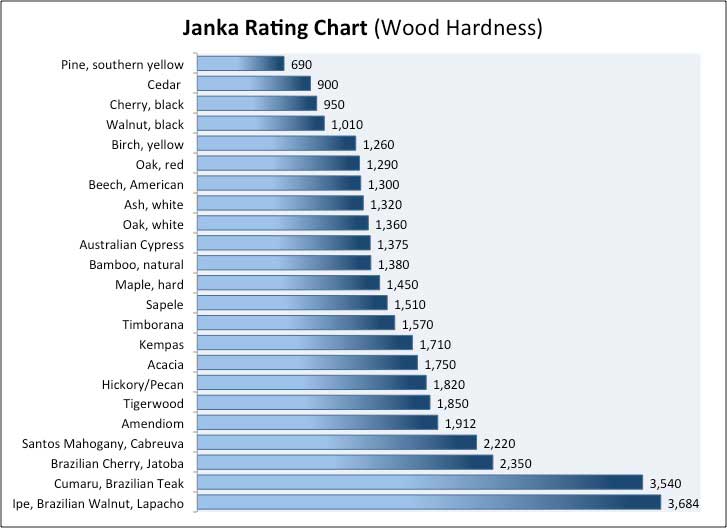

The Janka test measures the amount of force required to embed a steel ball halfway into a piece of wood. The Janka Hardness Scale refers to a range of numbers from 0 to 4,000, with 0 being the softest wood and 4,000 being the hardest. The Janka Scale is the industry standard method used to determine the durability and strength of hardwood floors and how resistant to dents, scratches, and wear that a type of wood will be. Woods with a higher Janka rating are harder, more scratch resistant, and more durable.

So, if Janka rating is the industry standard for flooring durability why not just buy flooring with the highest rating on the scale? Well, it’s not that simple…not even close.

Pitfalls of the Janka Rating

While Janka ratings can be helpful for determining the durability of a solid hardwood floor, don’t choose your floor based solely off these ratings. A higher Janka rating does not equal a higher quality floor.

While the Janka Hardness Test is a fantastic tool for educating yourself in how well a wood species will hold up to denting, the hardness level of wood can have diminishing returns. The species of wood is only one factor in the overall durability of a floor and how well it will look over time.

Other factors to consider:

- The type of finish

- The floor’s construction (engineered vs. solid)

- The traffic level in the home (kids, pets, etc.)

- How well the floor is cared for and maintained

Floor Finish

So you chose a hardwood that has a superior Janka rating, installed it, and now it’s time to finish. This can have an enormous impact on durability. No matter what type of wood species you choose, your floor’s finish will also play an important role in its durability. The finish is your floor’s first line of defense against dents and scratches and will bear most of the wear and tear from daily use. Whether you’re considering a solid or an engineered hardwood, finish will be a huge factor in overall durability. Then others may be pre-finished, especially engineered. The quality of finish on engineered, and other pre-finished wood floors, varies greatly.

Durable finishes to look out for include: aluminum oxide, urethane/polyurethane, and acid-cured finishes. Certain flooring brands might also have specially developed finishes for their products – or pre-finished in the factory. The hardest wood floor finish is aluminum oxide, but it only comes on prefinished boards. If you want something durable you can add after installation, acid-cured is your best bet. The key to the longevity of any type of wood floor is a maintenance coat when a traffic pattern begins to show in high traffic areas.

Flooring Construction

Quality of construction is a key factor for hardwood durability. Engineered floors are among the most durable wood floors, but are an exception to the Janka scale. Personally I tend to favor engineered flooring above all others due to their resistance to moisture, and in many cases superior factory finish.

Unlike a solid hardwood, engineered hardwood is constructed by layering softer wood under a veneer of the chosen wood species. Because of these different layers of wood materials, which vary across flooring brands, it’s difficult to determine an industry standard of hardness for engineered hardwoods using the Janka scale.

If you are shopping for an engineered floor, don’t focus on Janka ratings. While the Janka ratings may give you some idea of how well the top veneer of an engineered hardwood may hold up against denting and scratching, you need to remember the test was performed on a solid piece of wood. Look more for a top-quality manufacturer who not only has a 1/4″ wear layer but also is known to have a tough finish.

Even if the Janka scale can’t be used to accurately measure the hardness of an engineered hardwood, this does not make engineered hardwood a “bad” or “less durable” choice. The advantages of engineered in some cases may give it an advantage over solid hardwood.

- Because of their layered construction, engineered hardwood expands and contracts to better resist damage from humidity and temperature fluctuations.

- Engineered hardwood is more resistant to moisture, and can be installed over concrete where solid floors are not recommended.

- Engineered floors are pre-finished in a factory with products like aluminum oxide that are typically superior to a finish you’d get in your home (in the case of un-finished hardwood flooring).

Laminate and vinyl flooring (considered extremely durable) aren’t rated by Janka at all. Quality of construction and finish is therefore paramount to their strength – so much that they don’t even use Janka scale.

Mohs Hardness Scale

Janka ratings don’t apply to vinyl flooring because the Janka test is specifically designed to measure the hardness of solid wood, and vinyl is a completely different material. Instead, the hardness of vinyl flooring is usually measured using the Mohs hardness scale, which is better suited for non-wood materials but still used for wood in some cases.

A Mohs rating for flooring refers to a scale used to measure a flooring material’s resistance to scratches, with a rating ranging from 1 to 10, where 1 is the softest and 10 is the hardest; generally, a higher Mohs rating indicates a more scratch-resistant floor, with a rating of 7 or above considered ideal for most residential applications.

Examples of Mohs ratings for different flooring materials:

- Hardwood flooring: Typically around 4-5

- Vinyl flooring: Usually between 2-3

- Porcelain tile: Can reach 7-9

- Ceramic tile: Often falls within the 7-9 range

AC Rating

Laminate flooring hardness is measured using an “AC rating” (Abrasion Class), which ranges from AC1 to AC6, with AC5 being the most wear-resistant and considered the “hardest” option; for residential use, AC3 is typically considered the standard for heavy traffic areas, while AC4 is suitable for moderate commercial use. This is important when considering durability of hardwood flooring due to the fact AC Rating is primarily driven by the product finish.

Typical AC ratings:

- AC1: Light traffic, best for guest rooms or bedrooms with minimal use.

- AC2: Moderate traffic, suitable for bedrooms with regular use.

- AC3: Heavy residential traffic, ideal for most living spaces like kitchens and living rooms.

- AC4: Moderate commercial traffic, suitable for offices or shops with moderate foot traffic.

- AC5: Heavy commercial traffic, best for high-traffic commercial areas.

Other Issues to Consider: The Workability of Various Hard Woods

The benefits of choosing a species of wood with the highest Janka rating for flooring needs to be weighed with the difficulties in working with it. One example is IPE wood, which has one of the highest Janka ratings. It can be an absolute nightmare to work with if you do not have the right tools and experience. It’s difficult to nail down, and refinishing is a bear. Not to mention without a very good finish it changes color over time. Species with a higher Janka rating compared to other wood species is not as flexible, or resistant to moisture.

While a higher Janka rating can indicate a more durable floor, there are notable disadvantages:

- Less Flexible: Woods with very high Janka ratings can be inflexible and more likely to split.

- Installation difficulty: Harder woods like hickory can be difficult to cut, and sand or refinish.

- Cost: Hardwoods are generally more expensive.

- Conditions: The Janka test doesn’t account for how wood reacts to environmental factors like humidity, which can cause wood to expand and contract over time.

When choosing a floor, consider aesthetics and price as well as species. A hardwood floor is a big investment for your home, so you want to choose a floor you will love, not just the hardest species!